Last Wednesday, Max and I decided to start the “Kentucky Bourbon Trail”. It will take us to six distilleries throughout central Kentucky. We decided to split it up and visit 3 distilleries this week and then the other three next week.

So how did it begin?

In 1999, the Kentucky Distillers’ Association formed the Kentucky Bourbon Trail tour to give visitors a firsthand look at the art and science of crafting Bourbon, and to educate them about the rich history and proud tradition.

It began in the 1700s with the first settlers of Kentucky. Like most farmers and frontiersmen, they found that getting crops to market over narrow trails and steep mountains was a daunting task.

They soon learned that converting corn and other grains to whiskey made them easily transportable, prevented the excess grain from simply rotting, and gave them some welcome diversion from the rough life of the frontier.

Since then, generations of Kentuckians have continued the heritage and time-honored tradition of making fine Bourbon, unchanged from the process used by their ancestors centuries before.

So how did it get the name Bourbon? Well, one of Kentucky’s three original counties was Bourbon County, established in 1785 when Kentucky was still part of Virginia.

Farmers shipped their whiskey in oak barrels — stamped from Bourbon County — down the Ohio and Mississippi Rivers to New Orleans. The long trip aged the whiskey, with the oak wood giving it the distinct mellow flavor and amber color.

Pretty soon, whiskey from Bourbon County grew in popularity and became known as Bourbon whiskey.

In 1964, Congress officially recognized Bourbon’s place in our history and our future by declaring it a distinctive product of the United States, and made it “America’s Official Native Spirit.”

Now, all Bourbon is Whisky but not all Whisky is Bourbon. To “ Officially” be classified as Bourbon it has to be:

1. Made in the United States

2. Aged in a White Oak Charred Barrels

3. 51 percent corn

4. Aged for at least 2 years

5. Can not be distilled higher than 160 proof

6. Must go into the barrel at no more than 125 proof

7 Must be bottled at no less than 80 proof

We left around 9:30 am on a very pretty sunny day. We decided to go to the Jim Beam Distillery first because it was the farthest away. Besides, after all the samples we will be having we figured we better finish up with the one closer to the campground.

The ride up to Clermont was awesome. The road we took, took us through some very nice rolling hills and curvy roads. A nice change of pace from Indiana’s flat straight roads.

At the Jim Beam Distillery the first thing I learned was that there are several labels of Bourbon that each distiller makes. There are so many I could not even begin to keep track.

Jim Beams home

This is the worlds smallest working still. It is registered with the ATF and is licensed to operate. They said it would produce about a quart after about three days. It is made from bronze.

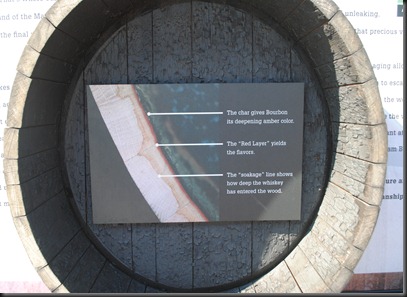

This is the inside of the charred barrel

The barrels are charred on the inside and the Char gives the Bourbon its color. The longer it is aged, the darker it will be. There is a red line under the Char and that also adds flavor.

One of the 48 Rack Houses on site. This is where the barrels are stored.

When the bourbon is stored they will lose anywhere from 15 to 25 percent due to evaporation. They call this loss the “Angels Share”

Another thing that happens with all of the evaporation is, that it makes the tree trunks and limbs turn black for up to a half mile radius. It does not hurt the trees any.

Back during prohibition the “Revenuers” would look for black trees to see if there was a still in operation close by.

Barrels stored in the Rack House. The plugs in the barrels have to be to the top. The barrels are 14 deep in each row. The worker knows how to position the barrel so the first one in the rack will end up at the end with the plug to the top.

After the tour we ended up at the tasting bar.

Max does not like Bourbon at all but she was a trooper and tasted all of the samples.

Jim Beam was fairly nice but they did not show us the actual processing.

Heavens Hill Distillery.

The Heavens Hill Distillery was basically a information and welcome center. They gave a brief tour of the center which covered the history of Heaven Hill and the process of making bourbon.

Here is a special bottle that we could have bought. It was only $129.00. I passed.

After the tour of the center we were able to have a sampling. I thing I tried 5 different ones. Plus Max’s left overs.

As you can see, she does not like it to well.

Now one thing I forgot to mention is that the Bourbon has to be aged in new barrels. They can not be re-used. So after a barrel is empty most distilleries turn around and sell the barrel to the Scotch distilleries in Scotland.

Makers Mark.

By far the best distillery tour so far. They actually tack you through the process.

The distillery property is just beautiful.

Back in the late 1800’s they used to charge a small toll to cross the property. On the way through the property the people would stop by this little building to get a jug full of whisky. Basically it was the country’s first liquor store.

The fermentation vats are made out of 125 year old cypress wood. Each one goes down through the floor about 20 feet. In each vat is a different stage of the fermentation process.

We were even able to taste each stage.

When it is ready it will be loaded into the still itself.

If you look closely you can see the 160 proof moonshine or White Dog as they call it pouring through the glass.

Inside the bottling process the bottles are turned upside down. They are rinsed with bourbon to make sure they are clean.

Here the bottles are being filled.

After the label and cap is put on, each bottle is hand dipped in wax to give Makers Mark it’s distinctive wax drip.

The finished product.

Enjoying the tasting.

Makers Mark put on a great tour and we really enjoyed this one.

Hopefully this next week we can get the other three distilleries in. When you go to the first one you can ask for a “Passport” to have each distillery on the Bourbon Trail stamp. When you get to all 6 of them you can send in the passport and the distillery association will send you a free T-shirt.

Work at Amazon is going fairly well. We are sore and tired. We do not have much time once we get home. We go to bed pretty early and it is hard for me to update the blog frequently.

Enjoy Your Day!

3 comments:

What a great post! This is going on the "things to do" list. Catherine hates bourbon. But knowing her, she will be a sport just like Max. Glad you are enjoying your days off.

Hey Dave we did the Makers Mark distillery as well and you are right it is a great tour. Enjoy the next 3. I hope Max is driving with all that tasting you are doing :)

yeah, about driving...who does the driving after a tasting tour? :-)

Post a Comment